A few years back, I had just finished a pristine roofing project when my younger nephew came up to me with his phone, showing me a funny roofing video on his TikTok app.

I remember laughing out loud, thinking, “Isn’t TikTok for teenagers dancing and singing?”

My nephew slyly replied, “TikTok is for everything, even roofing.”

While I was far from sold by his assertion, I remember gaining a curiosity about this social platform at that very moment.

Today, that curiosity has transformed into a full-on recognition that TikTok for Roofers is absolutely a marketing tool — and one that is a whole lot more enjoyable than “Traditional marketing methods.”

As a proud member of Roofer’s Guild, I will outline seven reasons all roofers should consider using TikTok in 2024.

But first, we have to answer the most essential question:

Key Takeaway

TikTok for roofers is a valuable advertising and marketing tool to help your company expand brand awareness and generate more roofing leads.

Do Roofers Need TikTok?

TikTok is a popular social media platform that will only get more popular. And as a marketing rule of thumb, you should be present where the consumers are.

As of 2024, TikTok has 1.4 billion users, which is expected to reach 1.8 million by the end of the year.

TikTok is known for short, video-based content, which presents an opportunity for roofing contractors. But it goes much deeper than that.

Users spend more time on TikTok than all social media platforms, averaging 55.8 minutes per session. For contractors serious about getting in front of more eyeballs, the appeal of this platform is obvious.

TikTok should be a part of your content/social media marketing strategy, along with Instagram, Facebook, and Linkedin.

Reasons to Use TikTok for Your Roofing Company

Running a roofing company presents countless challenges; some you see coming and others you don’t. Let’s be honest: TikTok should not be your top priority (nor should any social media platform).

However, if you aim to expand brand awareness and generate more leads for your roofing business, you should absolutely pursue TikTok.

Below are six convincing reasons for roofing companies to use TikTok.

1) TikTok Ads Can Generate Roofing Leads

The best reason to use any social platform, including TikTok, is to generate roofing leads. TikTok Ads allow roofing companies to run billboard-style ads directly in the users’ feeds.

Because TikTok is an addictive social media platform, users spend hours scrolling their feeds, which can include exposure to your ads.

As with Facebook or Instagram Ads, it’s essential to create attention-grabbing video ads that immediately hook the user.

It’s even more critical with TikTok, as users have the shortest attention span of any other social media user.

Installing a TikTok pixel on your website is a great way to optimize your ad budget properly. When TikTik users visit your website, they can be retargeted via the TikTok app.

2) TikTok is User-Friendly

One of the great things about TikTok is that creating a profile and post is straightforward.

With TikTok, you won’t need to employ any experts. The platform gives you all the tools you need to create engaging content.

You don’t need to know anything about coding or have any experience in web design.

As long as you have a basic smartphone experience, you will find TikTok very intuitive and user-friendly.

3) TikTok Helps you Reach your Target Demographic

There are about 80 million Americans who use TikTok every month. About 60% of those users are between 16 and 24.

As a roofer, this isn’t your target demographic. But 26% of TikTok users are between 25 and 44, which is your target demographic.

We know what you are thinking: 26% doesn’t sound like much. But when you consider that 26% of 80 million is 20,800,000, you realize you are still dealing with a vast pool of people.

People between the ages of 25 and 44 will most likely be first and second-time homeowners: the same people who are very likely to have many questions about their roofs.

4) TikTok Helps With Local Targeting

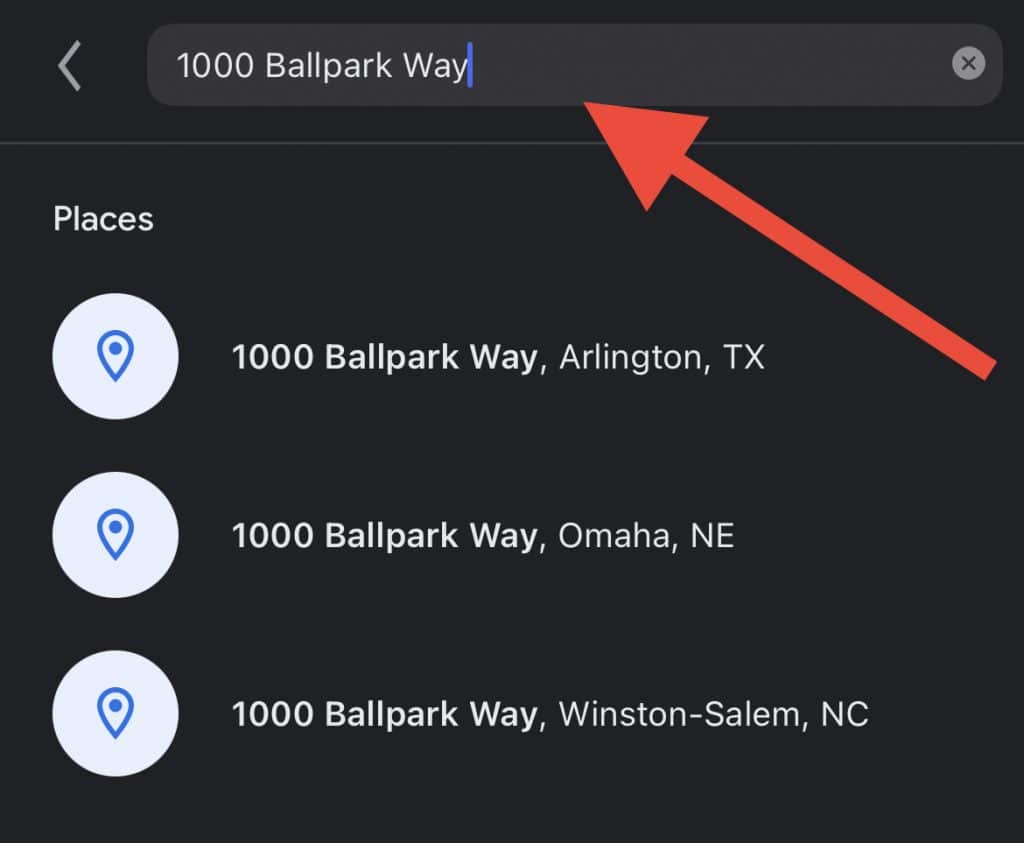

With TikTok, you can aim your content (and your ads) at people in your direct vicinity.

For example, we know that it wouldn’t do a roofing company much to have their content seen by someone in a different state.

But TikTok allows you to target users in your city, town, or county so that the people most likely to hire you will see your content.

Local targeting is part of what makes it a great local SEO and marketing tool.

Aside from location, you can filter who sees your content by criteria like age, interests, and gender. First-time users should try location filtering initially.

Then, however, you can start fine-tuning your demographic targeting as you get a better sense of your audience.

5) Roofers Can Repurpose TikTok Content

If you create something specifically for TikTok, you can use it on other platforms like Instagram.

Suppose you make a particularly popular or helpful video (based on the number of views and comments). Consider publishing it on your website or your company’s YouTube channel to maximize its reach.

YouTube offers a variation of TikTok content with YouTube Shorts, which are 60-second or fewer videos that serve a similar purpose to TikTok videos.

Users quickly consume these kinds of videos by browsing through the YouTube Shorts section.

TikTok videos are commodities you can spread across all your online outlets to increase visibility for your company.

While recycling TikTok videos may not always be the best idea, it’s good to understand that it is always an option.

6) TikTok is a Great Platform for Instructional Videos

Instructional videos and short “how-to” guides are viral on TikTok, especially after the pandemic.

As a result, people are willing to use the platform they already spend a lot of time on to learn to do simple tasks.

The how-to format of videos provides a golden opportunity for roofers to make guided videos regarding roof maintenance.

Many people have questions about their roofs, and new homeowners will likely take to TikTok to answer those questions.

The only question now is: will you be the one to answer them?

7) People Buy Through TikTok

Will TikTok earn you more customers? That depends on the effectiveness of your posts. But what is certain is that TikTok users are more than willing to use the app to make purchases.

TikTok is the number one platform for purchases of goods and services. Not only that, many TikTok users follow businesses they purchase from.

While social media won’t convert at the same rate as your website, it can funnel new leads into your business and help grow your brand.

How Roofers Can Get Started With TikTok

TikTok for roofers is undoubtedly a powerful and essential tool in 2024. Some contractors consider social media a waste of time, but the influence on your brand can be significant.

Roofing business owners that expand brand awareness through platforms like TikTok gain an advantage.

You can get started with TikTok advertising by visiting TikTok for Business. Reach out to Roofer’s Guild with any questions.